How Does A Heat Sink Work?

The devices that we had in ancient times are very sensitive to heat. They mostly become burnt with overheating or become less efficient with time due to heat that is created in them. So, people had to be careful, they used the device after intervals of time so it would not heat up with continuous use.

Technology and advancement have improved a lot. Now we have heat sinks that are specifically installed in the electric components to manage the output heat dissipation. You can get custom heat sinks that are made according to your provided criteria or demands. But before this, you should completely understand how a heat sink works. For this purpose read the given article.

Working Of a Heat Sink

As described earlier the heat sink is just working to move the heat away from any electrical component but it goes through a complete process of steps. We can explain its working in four basic steps which are described below:

Heat Is Generated By the Source

The first step is heat generation. The electrical device in which the heat sink is installed or attached generates heat that is needed to be removed from the system continuously to prevent any damage. Heat is mostly generated at a high level when the device or the system is working for a long period of time.

The source that is generating heat can be an electrical, mechanical, or chemical source. It can be a nuclear or solar source. Friction can also generate heat that needs to be removed from the system.

Move Heat Away From the Source

Now in the next step heat is transferred away from the source that is creating the heat. Here the heat sink works to get the heat from the source by using heat transferring ways. Here mostly the natural conduction process is involved.

The conduction process is directly affected by the material of the heat sink. As every material has its own thermal conductivity because of this reason heat sinks are made from high thermal conductivity materials like aluminum and copper to get possible satisfactory results. It is recommended to get a custom aluminum heat sink for the best possible results.

Heat Distribution

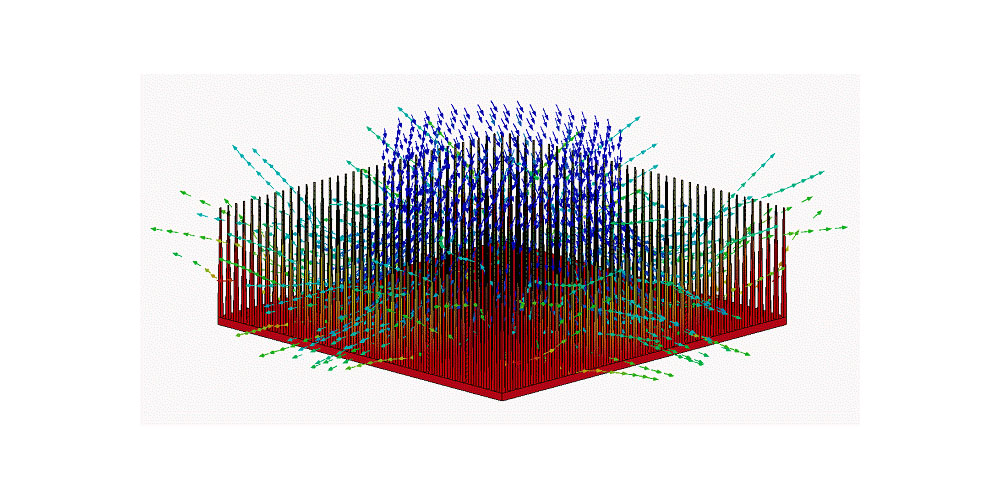

Now the heat moves throughout the heat sink by using a natural conduction way of heat transferring. The transfer of heat is carried by the thermal gradient from a higher temperature to a lower temperature involvement. It means that the heat sink will be hotter near the source and it will be cooler to its extremities.

Move Heat Away From the Heat Sink

The process of moving heat away from the heat sink is dependent upon the temperature gradient of the heat sink material and the type of fluid working which is mostly air or any non-electrically conductive liquid.

This is what will happen at that time:

-

The working fluid will move across the surface of the hotter side of the heat sink and the heat will transfer from the heat sink surface into the surrounding fluid by using the thermal diffusion or convection way of transferring heat.

-

Here the transfer of heat from the heat sink into the fluid is totally dependent upon the temperature gradient so if the surrounding temperature whether it is air or a liquid is not cooler than the heat sink temperature then there will be no convection or heat removal. Made a selection of the heat sink to keep in mind this also.

-

Another thing that can affect the heat removal at that step is the surface area of the heat sink. If the heat sink has a larger surface area then it will cause an increased area for the convection and thermal diffusion of heat.

Ending Remarks

Heat Sink is no doubt a crucial part that plays a significant role in removing unnecessary heat and maintaining the temperature of an electrical device. More information about its working is provided in the above article.